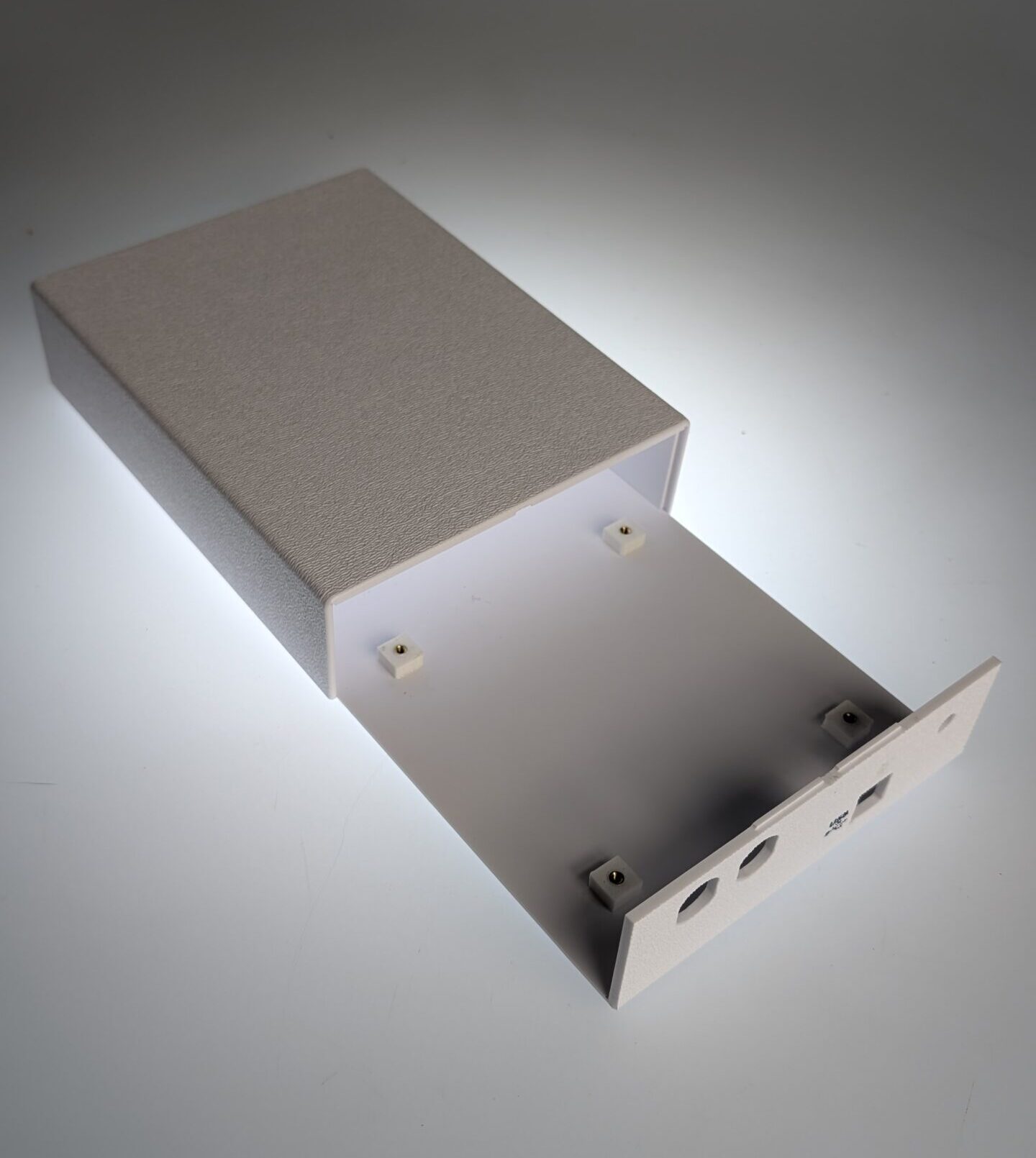

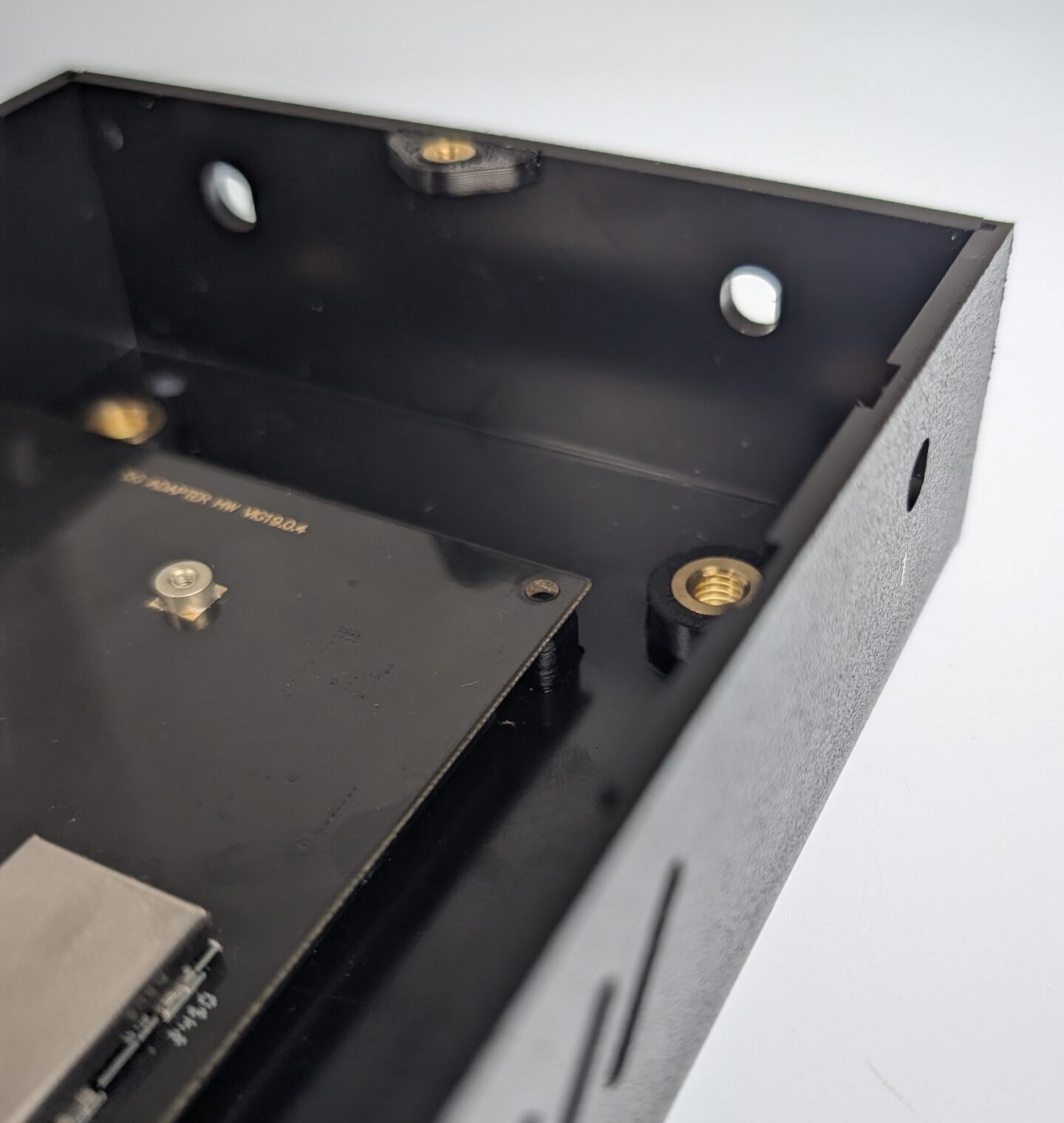

Many electronic assemblies require standoffs—raised supports that lift circuit boards or components off the enclosure surface—to provide clearance, ensure proper airflow, and accommodate fastening hardware. These standoffs often include inserts or threaded features to securely attach the board in place.

Using 3D printing to produce standoffs offers significant advantages. It allows rapid manufacturing of custom-designed standoffs tailored to your exact specifications, including precise dimensions, integrated inserts, and complex geometries that might be difficult or costly with traditional machining. This speed and flexibility help keep your production lines running smoothly by minimizing machine downtime and reducing lead times.

Whether you need small quantities for prototyping or larger runs to support full-scale assembly, 3D printing enables cost-effective, high-volume production of standoffs, ensuring your boards are properly supported and securely fastened throughout the manufacturing process.

“Patrick and staff were very accommodating, they took my idea and made it a living breathing reality in record time. It is ready for presentation. I would recommend this company to anybody Great job guys!"

Wayne Gaither - inventor of the Ultimate Blue.