Material

ABS- Acrylonite Butandiene Styrene

ABS (Acrylonitrile Butadiene Styrene) is an extremely popular material because of its relatively low cost and favorable mechanical properties such as impact resistance, toughness, and rigidity. Its chemical resistance is also very good and it holds up well outdoors and won’t fade when exposed to sunlight. This sets it apart from its cheaper cousin, PS (Polystyrene). It is available in a variety of colors, gloss levels and textures. It is easy to cut, weld and form which is why it is the material we recommend most often. Last but not least, it is recyclable and there is steady demand for reclaim.

PC-ABS – Polycarbonate Acrylonitrile Butandiene Styrene Blend

PC-ABS (Polycarbonate Acrylonitrile Butadiene Styrene Blend) is ABS (see above) with some PC added to it. The primary reason is that ABS will burn, whereas PC is self-extinguishing. Blending the two makes for a flame-retardant material that meets Underwriters Laboratories (UL) flammability ratings, most importantly UL94-V0 which is often required in hospitals and other high-traffic areas. The PC also adds stiffness and higher temperature resistance. However, it is more expensive and mostly used when flammability is an issue.

PVC – Polyvinyl Chloride PMMA – Acrylic PC – Polycarbonate PETG – Polyester

PC, PMMA , PETG and PVC are popular clear grades with PC (Lexan) being the top choice when strength and impact resistance are critical. Acrylic (Plexiglas) is preferred when optical properties and appearance are more important. PETG also offers good clarity and impact resistance at a price-point that falls in between the lower priced and brittle Acrylic and the higher-priced and more impact resistant PC. Clear PVC is mostly used where chemical resistance is the primary concern.

Polyethynes

HDPE (High-Density Polyethylene) and UHMW (Ultra-High-Molecular-Weight Polyethylene) are part of the polyolefin family and their properties are the result of different molecular weights. HDPE is relatively soft and has a low friction coefficient which makes it ideal for bumpers, guide rails, chutes and other material conveyor applications. Food grade varieties are often used for cutting boards and other food processing applications. UHMW is more rigid and stands out with its self-lubricating properties and high wear resistance.

Engineering Grade Materials

POM (Acetal), PA (Nylon) and PEEK (Ultem) are called such because they provide qualities needed in certain technical applications. In the case of Acetal it is high dimensional stability and low moisture absorption. Great machinability and a low coefficient of friction make it a popular choice for bushings and gears. Polyamide has exceptional tensile strength and is a very good electrical insulator. Ultem is also an excellent electrical insulator that will stand up to much higher temperatures than most other polymers.

Expanded Material

E-PVC (Expanded PVC) is a closed cell PVC foam board that is very well suited for large, light-weight, non-structural parts and signage applications. The faces are non-porous and sheets are perfectly flat which makes E-PVC are great substrate for printing. It is also available in a wide range of colors and gauges. Kiosks made from thick-gauge E-PVC are superior to their MDF counterparts in that they are lighter and not susceptible to water damage. E-PVC panels are also often used as mounting boards for monitors and other signaling devices.

Composite Material

ACM (Aluminum-Composite Material) is most commonly made with a PE (Polyethylene) core and thin Aluminum skins on both faces. Well known trade names are Dibond and Alucobond. ACM panels offer great flatness and stiffness with minimum weight. They hold up very well outdoors and are available in a wide range of colors and brushed metal finishes. They are popular for architectural applications and signage with long service-life requirements. ACMs can also add a high-tech look to many of our plastic housing types.

SERVICES

Custom Design and CAD Work

Custom Design and CAD Work is where most of our projects start. An idea, sketch or mock-up usually is enough for our designers to come up with 3D CAD rendering which becomes the basis for refining the details with our customers. What sets us apart from our competitors is that these CAD files are deliverables to our customers which means they own them and can explore all manufacturing options early on. This leaves the door open to move the project from our process to another one should volumes or requirements change. We take pride in being a launch-pad.Custom Design and CAD Work is where most of our projects start. An idea, sketch or mock-up usually is enough for our designers to come up with 3D CAD rendering which becomes the basis for refining the details with our customers. What sets us apart from our competitors is that these CAD files are deliverables to our customers which means they own them and can explore all manufacturing options early on. This leaves the door open to move the project from our process to another one should volumes or requirements change. We take pride in being a launch-pad.

Small-Batch and Just-in-Time Delivery

Small-Batch and Just-In-Time Delivery is where our process shines. This is because our CAD-driven CNC machining and thermo-line-bending process requires no fixtures or set-ups. As a result even small quantities of parts can be manufactured cost effectively and quickly. Many of our customers choose blanket purchase orders with release dates that are flexible – this allows us to use capacity when it is available to manufacture products or sub-assemblies that are held in inventory to be shipped on short notice when needed. This is just-in-time made easy.

EMI (Elctromagnetci Inteference) Shielding and Custom Coatings

EMI (Electromagnetic Interference) Shielding and Custom Coatings are often the reason for staying with traditional sheet metal housings. What many engineers don’t know is that plastic surfaces can easily be painted or coated. Polyurethane based paints can be applied by spray painting and add chemical resistance as well as the option to dial in textures. This makes it possible to match these parts to the powder coating of sheet metal pieces for a seamless look. Very effective EMI protection can be achieved with a Nickel-based coating on the inside.

No Time-Limit CAD & CAM File Backups

No Time-Limit CAD & CAM File Backups on-site and in the cloud is what we do for all our projects and revisions. In combination with a standardized material inventory that we have maintained over many years this means that products that haven’t been ordered for a long time can quickly be reproduced. We are also able to restore earlier revision levels for replacements or re-runs of an older design if needed. On many occasions we have been able to help customers restore their engineering information after a data loss by accessing our backups.

Reverse Engineering

Reverse Engineering is often required when a part is no longer being manufactured. We are frequently able to provide a suitable substitute at low cost even if the required quantity is small. Sometimes it may also mean coming up with a variant of a part that is needed in smaller quantities than the original. The same goes for accessories with a lower demand. It is also not uncommon for customers to enlist us as a secondary supplier in the event of a supply chain disruption. Since we and all our suppliers are domestic we can provide some peace of mind for critical plastic parts.

Contract Assembly and Custom Packaging

Contract Assembly and Custom Packaging is something we can do that in many instances will reduce the cost and lead time of the finished product dramatically. When just a few extra parts are needed complete the product it may make sense to have them installed during our assembly process. That is frequently the case with hinges, locks, handles and LED lights. Some of our customers take it one step further and have us source the final packaging so that the product does not have to be re-packaged at the customer’s fulfillment center.

Third Party Plastic Fasteners, Hinges, Handles and Switches

Third Party Plastic Fasteners, Hinges, Handles and Switches are available in a variety of polymers and finishes and we usually have a matching material. The result is a look that rivals the appearance of mass produced branded products allowing some of our smaller customers to keep up with larger competitors. This is often important for pilot runs of new products that are used for trade shows and demonstrations to investors. For legacy products this can be an opportunity to upgrade the appearance, especially when switching from sheet metal to plastic.

PROCESSES

CNC – Compute Numberical Control

CNC (Computer Numerical Control) Machining has come a long way since its inception and today’s CNC machines use AI (Artificial Intelligence) to optimize cutting parameters and part arrays while being connected to the Internet for remote monitoring and troubleshooting. At ClickFold we use the latest generation of CNC machines which allows us to control the machining process directly from a 3D CAD model – the need for shop drawings and manual entry of machining parameters is eliminated. Design changes can be accommodated quickly by changing the CAD model.

3D Printing

3D Printing is a great complement to our other capabilities. While CNC machining offers great advantages when it comes to larger parts that can be cut quickly from sheet stock, 3D printing is ideally suited for smaller and more intricate parts. Combining the two offers the best of both worlds and since 3D printing filament is now available in a wide range of polymers and colors it is possible to match up CNC machined and 3D printed parts perfectly. 3D printed parts also allow for mounts that hold internal components in place that are difficult to hold in place by other means.

Digital Graphics Printing

Direct-to-Substrate Printing is one of our key advantages because it is an integral part of our process. As opposed to injection molding and sheet metal fabrication where graphics can only be applied after the product is finished, we UV-print directly on plastic parts prior to forming. This allows us to employ digital flatbed printing which is superior to silk screening or pad printing in that photographic quality graphics can be applied directly onto the plastic. This takes plastic part printing to a new level. Using UV-cured inks makes for extremely wear resistant prints and decorations that will not fade or degrade when used outdoors.

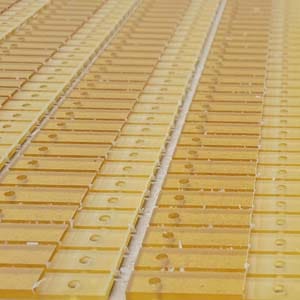

Thermo-Line-Bending

Thermo-Line-Bending is the process of using a thin heating element and heat shields that create a thermal aperture that focuses the heat on a defined line along which the part is bent to a specific angle. This allows for very precise bends and angles without distorting the surrounding material. The material texture and even printed graphics can be maintained. A V-notch cut from the inside insures accurate positioning of the bend and makes sharp inside corners possible. This is essential for parts designed to clip onto a mating piece or snap-lock a circuit board in place.

Solvent Welding

Solvent Welding differs from using adhesives in that a solvent is used to soften and liquify the mating surfaces which are then fused to form a solid weld once the solvent has evaporated. These chemical welds are not subject to aging or deterioration common to glued joints. A variety of solvents are used for ABS, PC-ABS, PVC, PC and Acrylic all of which solvent-weld well. Parts are fixated before the solvent is applied with an applicator syringe. Curing occurs within minutes and full bond strength is obtained within a few hours. A well executed solvent weld is almost invisible.

Asseembly, QC and Shipping

Assembly, QC and Shipping is where all the parts are fitted together and solvent welded or mechanically connected. This is also where third party components such as fasteners, hinges and latches are added. Fit and function are tested and tolerances checked. Graphics are checked for alignment and correct colors. In many cases our customers will provide samples of their circuit boards, displays or other components to have fit and function tested at this stage. Kitting the finished product with accessories is another service we can provide.

Edge-Finishing

Edge-Finishing is a secondary process which adds a radius, bevel or chamfer to the 90 degree cut of a CNC machine. This not only improves the appearance of the edge but also makes products more ergonomic and easier to handle, especially in the case of handheld devices. It is worth noting that these finishing touches often make a product appear as if it was molded which is desirable if the product is used in conjunction with other parts that are injection molded. Various radii, bevels, chamfers or steps for trim lines are available.